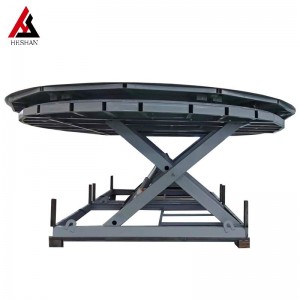

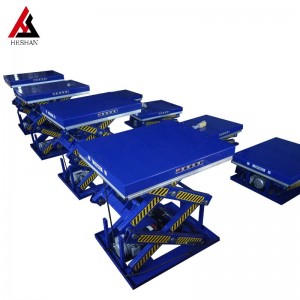

Isiteji Senziwe Ngokwezifiso I-Hydraulic Scissor Lift

Isiteji se-telescopic samukela uhlelo olusebenzayo lokuqondisa, ukuze igebe phakathi kwesiteji se-telescopic kanye nesiteji esinqunyiwe libe lincane phakathi nenqubo yokuhumusha, ukusebenza kuzinzile, futhi isivinini sishintsha kancane kancane.Idivayisi yokuvumelanisa iqhutshwa isivinini esiphansi kanye ne-torque enkulu, ukuze isiteji sihambisane ngokuphelele, sikhululekile, futhi sisendaweni ngesikhathi sokunwetshwa nokufinyela, futhi singakwazi ukufeza izinga ngokuzenzakalelayo.Ilungele izindawo zamasiko nezokuzijabulisa ezifana namahholo, izinkundla zemidlalo yaseshashalazini, amahholo anemisebenzi eminingi, izitudiyo, izindawo zamasiko nezemidlalo, amahhotela, njll.

Izici

Indlela yokuphakamisa yenziwe ngeshubhu elikhulu lensimbi ye-manganese kanye nepuleti lensimbi.

Ifakwe idivayisi yokuvikela ukuphepha ukuvimbela inkundla yokuphakamisa ukuthi ingalayishi kakhulu.

Ifakwe i-valve yokuvikela ukuphepha ukuvimbela ukugqashuka kwepayipi le-hydraulic.

Idivayisi yokwehlisa izimo eziphuthumayo uma amandla ehluleka.

Izinyathelo zokuzivikela

1. Phakathi nenqubo yokuphakamisa nokwehliswa kwesikhulumi, kwenqatshelwe ngokuphelele ukukhuphuka nokuzamazama.

2. Ngesikhathi sokulungiswa, ipulatifomu kufanele iphakanyiswe futhi iqine ngaphambi kokusebenza.

3. Yonke imisebenzi yokulayisha ngokweqile inqatshelwe ngokuphelele ngesikhathi kusetshenziswa ipulatifomu.

4. Uwoyela weHydraulic kufanele ugcinwe uhlanzekile, ungaxutshwa namanzi nokunye ukungcola, ngokuvamile ushintshwa kanye ngonyaka, sebenzisa i-N32 ebusika kanye no-N46 # uwoyela we-hydraulic ehlobo.

5. Uma ipulatifomu ihluleka, amandla kufanele anqanyulwe.

6. Kuvinjelwe ngokuqinile ukusebenzisa imishini ngokugula, futhi abantu abangewona abantu abavunyelwe ukuhlakaza futhi balungise izingxenye zokudluliselwa kwe-valve block ye-hydraulic.

7. Uma umsamo usetshenziswa phansi, kufanele kube nendawo eyanele yokukhuphuka nokuwa.Hlola ukuthi azikho yini izithiyo kulayini kagesi nasethangini likaphethiloli, ukuze ugweme ukuphuka kolayini nokuphuka kwepayipi phakathi nenqubo yokuphakamisa inkundla.

Imininingwane

Umbukiso Wemboni

Iklayenti Lokubambisana