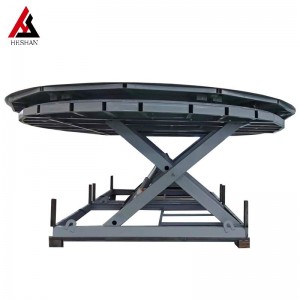

I-Heavy Duty Big Scissor Lift Table

Isiteji sokuphakamisa isikele esilungisiwe siwuhlu olubanzi lwemishini ekhethekile yomsebenzi wasemoyeni.Ukwakheka kwayo komshini wesikele kwenza iplatifomu yokuphakamisa ibe nokuzinza okuphezulu, inkundla yokusebenza ebanzi kanye nomthamo ophezulu wokuthwala, ukuze uhla lomsebenzi wasemoyeni lube lukhulu, futhi ifanele abantu abaningi ukuthi basebenze ngesikhathi esisodwa.

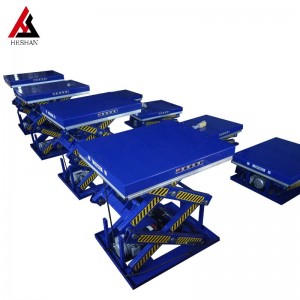

Kwenza ukusebenza kwasemoyeni kusebenze kahle futhi kuphephe.Umkhiqizo unesakhiwo esiqinile, umthamo omkhulu wokuthwala, ukuphakamisa okuzinzile, ukufakwa nokunakekelwa okulula futhi okulula, futhi uyindlela eyongayo nesebenzayo efanelekile yokuthutha impahla ukuze ithathe indawo yamakheshi phakathi kwezitezi eziphansi.Ngokwendawo yokufaka kanye nezidingo zokusebenzisa yesikhulumi sokuphakamisa, ukulungiselelwa okuhlukile kokuzikhethela kungakhethwa ukuze kuzuzwe imiphumela engcono yokusebenzisa.

Inkundla yelifti engaguquki idinga ukufakwa umuntu okhethekile futhi ingasetshenziswa ngemva kokulungisa iphutha.Indlela yokufaka yayo ihlukaniswe ngezinyathelo ezilandelayo:

1. Linganisa usayizi Kala ubukhulu bomgodi weplatifomu yokuwuphakamisa.Ngokuvamile, usayizi wetafula leplathifomu kufanele ube mncane kunosayizi womgodi lapho ufaka inkundla yokuphakamisa engaguquki.

2. Ukuze uphakamise, sebenzisa intambo yocingo ukuze ubophe ihhuku lesisekelo seplatifomu yokuphakamisa, uyiphakamise endaweni enqunywe kusengaphambili, ukhulule intambo yokuphakamisa ngemva kokuyibeka kahle, ulinde iplatifomu yokuphakamisa ukuze ingene emgodini, bese-ke. faka umgodi wokulungisa isikhundla kanye nomsebenzi wezintambo;uma kunesikhala emgodini Omncane, kuyadingeka ukuphakamisa phezulu kwetafula yesikhulumi sokuphakamisa umsebenzi ngaphambi kokusebenza.

3. Lungisa indawo Lungisa iplatifomu yokuphakamisa ibe yindawo efanele, edinga ukuthi inkundla yokusebenza yokuphakamisa kanye nomhlabathi kugcinwe kusezingeni, futhi igebe phakathi konqenqema lwesikhulumi kanye nonqenqema lomgodi lifaniswa kahle.

4. Ukuxhumeka ngokuyinhloko ukuxhuma ipayipi le-hydraulic, umthombo womugqa weswishi yokuhamba kanye nomthombo wokulawula umugqa.Ipayipi le-hydraulic elisuka endaweni yokuphakamisa lixhunywe kwipayipi le-hydraulic ebhokisini lokulawula, futhi umthombo wemigqa emibili osuka ebhokisini lokulawula uxhunywe ku-chassis yesikhulumi somsebenzi wokuphakamisa.Kumatheminali ezintambo phezulu, iplatifomu yokusebenza yokuphakamisa enenkinobho yokusebenza endaweni yokusebenza kufanele ixhunywe kumthombo womugqa wokulawula, bese uxhuma umthombo wolayini wemibala eminingi odonswe ebhokisini lokulawula uye endaweni yokuxhuma indawo yokuphakamisa. i-chassis yesikhulumi sokusebenza.

5. Ukulungisa iphutha Vula ukunikezwa kwamandla, hlola ukuthi ingabe iplatifomu ephakamisayo nendawo yokusebenza ephezulu isesimweni esihle yini lapho iplathifomu ikhuphukela ezingeni eliphakeme kakhulu, nokuthi ingabe ibanga phakathi kwengaphambili nangemuva kweswishi yokuhamba liyalungiswa yini ukuze kugcinwe. isiteji esiphakamisayo kanye nezinga eliphezulu lomhlabathi.

6. Ngemuva kokuthi ukulungiswa nokulungiswa kuqediwe, ngemva kokuqinisekisa ukuthi kulungile, lungisa isiteji sokuphakamisa ngezinsimbi zokunweba zensimbi, bese ugcwalisa igebe phakathi kwe-chassis nomhlabathi ngodaka lwesimende.

Umbukiso Wemboni

Iklayenti Lokubambisana